DTC B2430 LED Headlight LH Circuit Malfunction |

DTC B2431 LED Headlight RH Circuit Malfunction |

for Preparation Click here

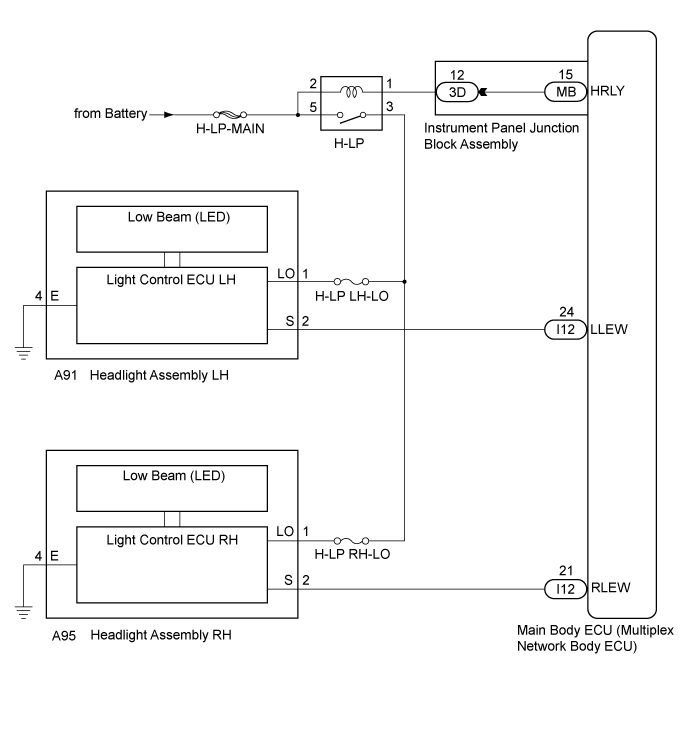

DESCRIPTION

These DTCs are stored when the low beam headlights do not illuminate, or a malfunction is detected in the communication between the headlight assembly and main body ECU (multiplex network body ECU).| DTC No. | DTC Detection Condition | Trouble Area |

| B2430 | Any of the following conditions occur after 20 seconds have elapsed since the ignition switch was turned ON:

|

|

| B2431 | Any of the following conditions occur after 20 seconds have elapsed since the ignition switch was turned ON:

|

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- DTC B2430 and B2431 are not stored if 20 seconds have not elapsed since the ignition switch was turned ON.

| 1.CHECK FOR DTC |

Clear the DTCs (Click here).

Check for DTCs (Click here).

Result Result Proceed to Both DTC B2430 and B2431 are not output A Both DTC B2430 and B2431 are output B DTC B2430 or B2431 is output C

|

| ||||

|

| ||||

| A | ||

| ||

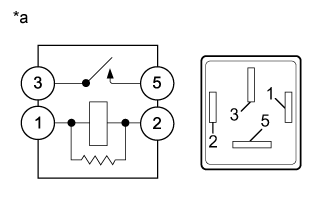

| 2.INSPECT H-LP RELAY |

|

Remove the H-LP relay from the engine room relay block and junction block assembly.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 3 - 5 Voltage not applied between terminals 1 and 2 10 kΩ or higher 3 - 5 Voltage applied between terminals 1 and 2 Below 1 Ω

Text in Illustration *a Component without harness connected

(H-LP Relay)

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (BATTERY - H-LP RELAY) |

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection Condition Specified Condition Relay Terminal 2 - Body ground Always 11 to 14 V Relay Terminal 5 - Body ground Always 11 to 14 V

|

| ||||

| OK | |

| 4.CHECK HARNESS AND CONNECTOR (H-LP RELAY - HEADLIGHT ASSEMBLY) |

Disconnect the A91 headlight assembly LH connector.

Disconnect the A95 headlight assembly RH connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Relay Terminal 3 - A91-1 (LO) Always Below 1 Ω Relay Terminal 3 - A95-1 (LO) Always Below 1 Ω Relay Terminal 3 - Body ground Always 10 kΩ or higher

|

| ||||

| OK | |

| 5.CHECK HARNESS AND CONNECTOR (H-LP RELAY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

Disconnect the 3D instrument panel junction block assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition Relay Terminal 1 - 3D-12 Always Below 1 Ω Relay Terminal 1 - Body ground Always 10 kΩ or higher

|

| ||||

| OK | |

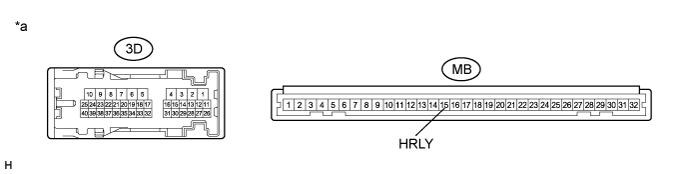

| 6.INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

Remove the instrument panel junction block assembly (Click here).

Remove the main body ECU (multiplex network body ECU) from the instrument panel junction block assembly.

Measure the resistance according to the value(s) in the table below.

Text in Illustration *a Component without harness connected

(Instrument Panel Junction Block Assembly)- - - Standard Resistance:

Tester Connection Condition Specified Condition 3D-12 - MB-15 (HRLY) Always Below 1 Ω

|

| ||||

| OK | ||

| ||

| 7.CHECK HARNESS AND CONNECTOR (HEADLIGHT ASSEMBLY - H-LP RELAY) |

Disconnect the A91 or A95 headlight assembly connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

LH Side (DTC B2430) Tester Connection Condition Specified Condition A91-1 (LO) - Body ground Ignition switch off, light control switch in head position 11 to 14 V RH Side (DTC B2431) Tester Connection Condition Specified Condition A95-1 (LO) - Body ground Ignition switch off, light control switch in head position 11 to 14 V

|

| ||||

| OK | |

| 8.CHECK HARNESS AND CONNECTOR (HEADLIGHT ASSEMBLY - BODY GROUND) |

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

LH Side (DTC B2430) Tester Connection Condition Specified Condition A91-4 (E) - Body ground Always Below 1 Ω RH Side (DTC B2431) Tester Connection Condition Specified Condition A95-4 (E) - Body ground Always Below 1 Ω

|

| ||||

| OK | |

| 9.CHECK HEADLIGHT ASSEMBLY (INPUT VOLTAGE) |

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

LH Side (DTC B2430) Tester Connection Condition Specified Condition A91-2 (S) - Body ground Ignition switch ON, light control switch in head position 11 to 14 V RH Side (DTC B2431) Tester Connection Condition Specified Condition A95-2 (S) - Body ground Ignition switch ON, light control switch in head position 11 to 14 V

|

| ||||

| OK | |

| 10.REPLACE HEADLIGHT UNIT |

Replace the headlight unit with a new or known good one (Click here).

Check for DTCs (Click here).

- OK:

- DTC B2430 or B2431 is not output.

|

| ||||

| OK | ||

| ||

| 11.CHECK HARNESS AND CONNECTOR (MAIN BODY ECU (MULTIPLEX NETWORK BODY ECU) - HEADLIGHT ASSEMBLY) |

Disconnect the I12 main body ECU (multiplex network body ECU) connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

LH Side (DTC B2430) Tester Connection Condition Specified Condition I12-24 (LLEW) - A91-2 (S) Always Below 1 Ω I12-24 (LLEW) - Body ground Always 10 kΩ or higher RH Side (DTC B2431) Tester Connection Condition Specified Condition I12-21 (RLEW) - A95-2 (S) Always Below 1 Ω I12-21 (RLEW) - Body ground Always 10 kΩ or higher

|

| ||||

| OK | ||

| ||